Process development scientists, faced with an increasing number of proteins or complex biomolecules, continuously search for robust purification methods that can be rapidly scaled for manufacturing. What are the optimal purification conditions for high throughput and yield? Which resin or resin combination best purifies the desired protein? How can an efficient, yet cost-effective process be established? The answer: use a systematic screening approach.

Several chromatography resins may be suitable for a given separation; however, specific physiochemical differences among resins can impact their performance, affecting purity and yield. Therefore, resin selection is critical for optimization of the purification process.

Screening is complicated by the number of resin products available, as well as the many other variables that can be considered in a purification workflow. For these reasons, investigators often utilize resins familiar to them or those recommended in the literature. Others may select the first resin that delivers satisfactory results in their process.

A systematic screening approach is key to finding the optimal resin for a specific purification process. The ultimate objective is to select the resin which delivers the best combination of many factors, such as yield, purity, processing time, and capacity. This is best accomplished by not only considering multiple resin candidates, but also optimizing the operating conditions for each resin screened.

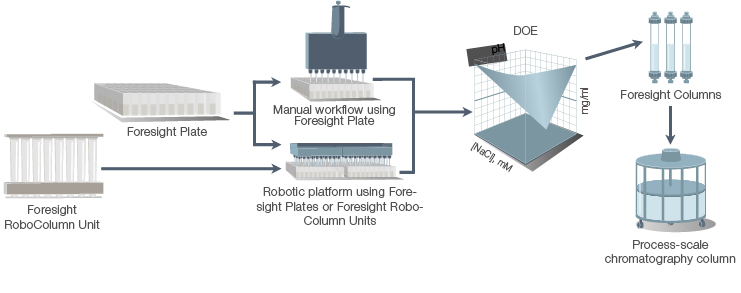

Purification scale-up workflow shows the use of high-throughput screening and design of experiment (DOE) to define an operational window for biomanufacturing.

Bio-Rad offers process chromatography resins in prepacked formats for the entire purification development cycle, from high-throughput resin screening to small-scale method development and scale-up optimization. Foresight Chromatography Filter Plates and Columns are designed to save process development time and enable high-throughput experiments with minimal sample usage.

To learn more, check out our resin screening tools.