How do you reimagine a technology that’s successful, accepted, and already in relatively widespread use? If the technology in question is cell sorting—a key method in immunology that’s now becoming more popular in other bioresearch areas—you “think outside the box” by designing to “fit inside the box.”

That’s a neat formulation for Bio-Rad’s effort to develop the S3 Cell Sorter, which was conceived to put the power of cell sorting into an easy-to-use benchtop instrument. But such neat formulations cover up the best parts of the story: the innovations that occurred along the way. These show that, even if you keep all the basic ingredients of an established technology, you can still put them together in surprising new ways that create big changes for researchers.

Watch this video to see how some of the design innovations in the S3 Cell Sorter came about, including a unique automated method for calculating drop delay.

A monster, but one you fall in love with

Thinking back over a long career in flow cytometry, Bio-Rad staff scientist Carol Oxford remembers the first time she saw a cell sorter. “You walk in and see this machine and it’s very intimidating,” she says. “It’s huge. It’s a monster.”

Staff Scientist

Bio-Rad Laboratories, Inc.

Despite her initial impression, Oxford also remembers how she gravitated to immunology and, as she explored the field as a college student, to “flow.” “[It was] such an interesting combination of immunology, instrumentation, and data analysis,” she says. “And once you learn how the technology works, it’s very exciting and the power is amazing. I fell in love with [flow cytometry] and I never left.”

After becoming an immunologist at the University of California-Davis, Oxford soon realized the need to develop a cytometry core facility at that institution. She spent the next twenty-five years building and running a core lab there, starting with a single FACS machine and finishing with two cell sorters and seven analyzers in three different locations.

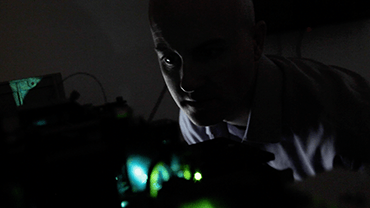

Bio-Rad Staff Scientist Carol Oxford and engineer Ed Marquette pore over an S3 Cell Sorter without its skin. Oxford came to Bio-Rad from her previous role as manager of the University of California-Davis Flow Cytometry core facility in order to work on the S3 Cell Sorter. “There’s so much about cell sorting that should have been automated years ago,” she says.

“One of the best things about being a core manager is helping researchers, seeing what their project is and how the science and art of flow cytometry and cell sorting can accomplish their goals,” Oxford says. “And one of the worst things is sitting and watching a sorter sort. There’s so much about cell sorting that should have been automated years ago.”

When she heard about the S3 Cell Sorter project, Oxford saw the opportunity to bring about this very change. And so, after many years as a core lab manager, she joined Bio-Rad to help create this better cell sorting experience.

A tiny drop delay, a big headache

Halfway across the country, in Ft. Collins, Colorado, Dan Fox, Director of R&D at Propel Labs, a biotechnology instrumentation company, began work on making a more automated, more accessible cell sorter.

Director of Research and Development

Propel Labs

“I remember back when I first became familiar with Dan Fox,” says Oxford. “I read one of his papers on digital electronics and I thought, ‘This guy is brilliant!’ He’s well known as an expert in the field.” Now Fox was leading a development effort in confronting the very problem Oxford described: the misery of having to sit for hours and watch a cell sorter sort.

Those monotonous hours stem mainly from the need to calculate and monitor drop delay during the cell sorting process, a laborious and exacting task requiring a well-trained technician. Cell sorters work by passing a sample containing cells in single file through a tiny column of liquid. A laser shines on the stream as it emerges from the nozzle, shortly before it begins to break into droplets, each containing an individual cell that’s then electrically charged and sorted using deflection plates. Accurately measuring the drop delay, the brief period between the laser illumination, the point of information-gathering about each cell, and droplet breakoff, the point when that cell becomes a discrete, sortable unit, is the key to getting a pure sort.

“Basically, you have these fast moving, tiny, tiny particles you’re trying to detect,” Fox says. “They’re moving 20 to 30 meters per second and are in the 1 to 10 (micrometer) range. You’re trying to look at this microscopic event flying through the air at high speed. It’s very hard to detect.”

At this speed and scale, it took a trained technician to calculate the drop delay either by counting calibration beads’ on a slide—a laborious process involving many trips between the sorter and a microscope—or using a camera to find or adjust the optimal point, a difficult feat due to both the speed and tiny magnitudes one must photograph. Automating either of these procedures proved too difficult or inaccurate; the best results were only computer assisted, not fully automated.

“One of the most important things to us in designing the S3 Cell Sorter was coming up with something that was better than what was already out there,” says Fox. “Our idea for the drop delay really evolved from turning the current approaches on their head.”

Discovering innovation in the waste stream

“Sometimes in the flow cytometry community—I’m guilty of this at times—we think of things the way we’ve always done them and we try to improve on the same system,” says Oxford. “Dan and his colleagues at Propel Labs, they thought about the drop delay problem completely differently. Sometimes an approach like that doesn’t work, but in this case it worked brilliantly.”

Left: Dan Fox, Director of R&D at Propel Labs, checks the lasers on an S3 Cell Sorter without its skin. The system has two lasers for sorting up to four colors at once. Right: Dan Fox and Nathan Gaskill-Fox, an engineer at Propel Labs, discuss the design of the S3 Cell Sorter, pictured on the monitor behind them.

“In a lot of efforts to come up with a better drop delay calculation, the work focused on either imaging the stream or trying to detect particles that were correctly sorted,” says Fox. “We realized that instead we needed to start with particles that were incorrectly sorted.”

Up to this point, no one had thought to utilize the waste stream in the cell sorting process as a site to calculate drop delay, but Fox and his colleagues soon saw its advantages. “Measuring in the waste stream is slower, it’s easier to detect. You can collect the particles and measure them where you want them,” Fox says.

In the method that resulted from this insight—now realized as the ProDrop™ technology on the S3 Cell Sorter—the sorter starts by setting a deliberately incorrect drop delay value that sends calibration beads into the waste stream. As the beads are measured there, the sorter starts changing the drop delay. The number of incorrectly sorted beads declines until it hits zero, then it sweeps past that and the number of beads in the waste stream begins to increase again. The best drop delay occurs at zero, the low point of the distinctive “V” shaped plot. With this method, Fox and his team had found a way to pinpoint the drop delay by looking not for a measurement, but for the absence of one.

“The accuracy of the drop delay is the key to the S3 Cell Sorter,” Oxford says. “It’s unique and very simple, but it gives you the best sort purity and recovery.”

A shared vision

Top: Other than loading the collection tubes, users of the S3 Cell Sorter control the instrument entirely through its ProSort™ software. Middle: The software presents an easy interface, in this case for adjusting the stream position. Bottom: The ProDrop™ drop delay calculation method achieves an optimal sort by measuring calibration beads in the waste stream. The zero-point in the graph pictured is the point where the drop delay value is correct for optimal sorting.

“In the beginning we were just looking for some advice on electronics,” Oxford says. “But the more we talked with Propel Labs, the more we realized that this partnership was going to be a lot stronger than engineering advice.

Scientific and engineering teams from Bio-Rad and Propel Labs met at CYTO 2012 in what turned out to be a fruitful gathering. The two companies became partners, bringing together Propel Labs’ novel engineering concepts and Bio-Rad’s longstanding expertise in producing and supporting research instrumentation.

“What I remember about CYTO is what a great match we saw between the two companies,” Fox says. “Bio-Rad had the same vision as we did, the same goal, which was to use this technology to enable more labs to do cell sorting.” Bringing together an engineering design startup with a global life science technology company proved a big step in making this vision into a reality.

“I think the partnership we have with Propel Labs is part of the new paradigm,” Oxford says. “You combine the strengths of a small company with a large company—Propel Labs’s very specific state-of-the-art expertise with Bio-Rad’s global manufacturing expertise and technical support. I think it’s a perfect partnership.”

Simple, but deceptively simple

“When I was first involved with the S3 Cell Sorter project, one of my worries was that it would be dumbed down,” Oxford says. “That somehow, because it was very simple there wasn’t the power behind it that other sorters had—especially the sophistication that the bigger cell sorters had.”

The S3 Cell Sorter is simple, in one sense. Because of improvements in everything from electronics to optics, Propel Labs were able to fit all the components of a cell sorter into a benchtop instrument. However, what’s inside the simplified exterior is far from dumbed down.

“The key to understanding the S3 Cell Sorter is in understanding where its simplicity comes from,” Oxford says. “It’s not going to replace the high-end multicolor, multi-laser cell sorting systems out there. The S3 Cell Sorter has two lasers, four colors, but it does those kinds of sorts very well. You’ve got the same high-speed electronics, the same Hamamatsu photomultiplier tubes, and these will give you the same sensitivity as a four-color sort on one of the larger systems.”

The ProSort software interface also serves to conceal the powerful processes going on in the background. “There can be tens of thousands of cells coming through per second that all have to be processed, analyzed, sorted,” Fox says. “There’s image recognition going on to keep the stream stable as it tries to change over time and temperature. There’s so much going on but when you look at the software you tend to forget about it, which is really the point of the system in the first place.”

To achieve this deceptive simplicity, Propel Labs brought in a team of software developers with one specific requirement: no experience with flow cytometry. “They would stop and ask all these questions,” Fox says. “Why do we do it this way? We’d answer, ‘well…because that’s how we’ve done it for 15 years.’ But is that the right way? So we’d have to stop and question our assumptions. And that way we had a total rethink of the best way to make software for sorting cells.”

Better results for researchers

“I think it’s much better for researchers to be able to run samples themselves, whenever possible,” says Oxford. “If they understand the instrument better, they understand their data better. That gives them a window into doing more science, they’ll do more experiments, and they’ll do better science.”

Susan Hunter (blue jacket), an engineer from Propel Labs, consults with Bio-Rad engineers on the Bio-Rad manufacturing floor.

By automating formerly complex processes like drop delay calculation, by streamlining the fluidics and electronics into a benchtop instrument, and by creating a simple interface that doesn’t require a trained technician to operate, the S3 cell sorter opens the door to this greater involvement by researchers who aren’t also flow cytometry experts.

“With the S3 cell sorter, now we have an instrument that allows the investigator to put their cells on the sorter and let the computer monitor the sorts, monitor the breakoff, move the tubes, do the really tedious parts of sorting,” Oxford says. “We can get back to the elegant parts of research: designing the experiments, working with applications and doing what we’re really excited about doing.”