Carbohydrates, among the most important components of foodstuffs, are a major source of energy and account for more than 70% of calories in the human diet. They also add crucial textural properties, such as crispness or smoothness, and influence physiological processes in the form of dietary fiber. In addition, carbohydrates contribute bulk, viscosity, and stability to emulsions as well as sweetness, water retention capacity, freeze-thaw stability, flavors, and aromas (BeMiller 2017).

Appearing as isolated molecules or associated with other molecules, carbohydrate molecules are classified according to the number of monomers they contain and are called monosaccharides, oligosaccharides, or polysaccharides. Glycoproteins are carbohydrates covalently attached to proteins while glycolipids are carbohydrates covalently attached to lipids. Some carbohydrates, when converted to monosaccharides, are digestible by humans; those that remain indigestible (polysaccharides) are known as dietary fiber (McClements 2003).

Why do we need to determine the type and concentration of carbohydrates in our food?

- To ensure prepared foods are acceptable within government regulations

- To inform consumers of nutritional content

- To detect authenticity or adulteration of components

- To maintain the quality of physiochemical properties such as sweetness, appearance, texture, and stability

- To facilitate economical production, as the prepared food industry prefers not to give away expensive ingredients

- To determine the efficiency of food processing operations

An important technique that enables detection of carbohydrate content in food and beverage samples is high performance liquid chromatography (HPLC). HPLC can provide data regarding product quality, contamination, or adulteration to aid quality control, labelling, and monitoring of production processes. To analyze small molecules, the type of HPLC column used will be indicated by the chemical nature of the compounds of interest.

Aminex Ion Exchange Resins, of polystyrene-divinylbenzene, can be used with a wide variety of water-soluble and partially water-soluble organic compounds to effectively analyze carbohydrates, organic acids, and other small molecules. Since their introduction in the 1970s, Aminex Columns have become the industry standard for carbohydrate and organic acid analysis (Table 1).

Table 1. Carbohydrate analysis columns and their applications. Content adapted from Bulletin 1928 Rev B.

| Carbohydrate Type | Analysis Application | Aminex Column |

| Monosaccharides | Sweeteners, such as glucose and fructose or sugar alcohol | HPX-87C |

| Cellulose-derived monosaccharides | Sucrose, lactose, galactose in dairy products | HPX-87P |

| Organic acids | Carbohydrates in solution with carboxylic acids, volatile fatty acids, short chain fatty acids, alcohols, and ketones, such as those present during fermentation | HPX-87H |

| Sugars | Sugars in samples with high salt concentrations, such as molasses | HPX-87N |

| Mono-, di-, and trisaccharides | Corn syrup and brewing wort or glucose, maltose, or maltotriose | HPX-87K |

| Oligosaccharides | Glucose polymers in corn syrup | HPX-42A |

| Mono- and disaccharides | Starch hydrolysates | HPX-42C |

Sensitive analysis of carbohydrates is critical in the food and beverage industry. For optimal analysis, a wide variety of carbohydrate analysis columns that provide high selectivity for specific carbohydrates are available. Research length (30 cm) columns provide high-resolution separation of complex carbohydrates in 20 minutes, while smaller columns provide separation of specific carbohydrates in 3 to 5 minutes.

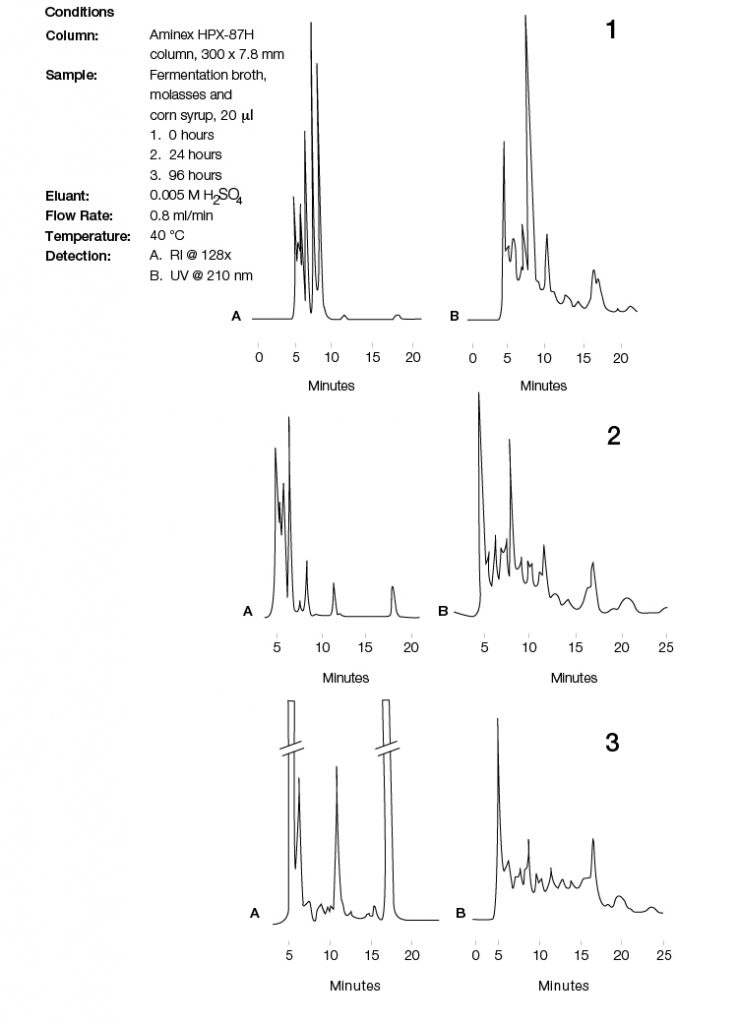

A fermentation broth consisting of a complex carbohydrate mixture containing molasses and corn syrup was monitored at 0, 24, and 96 hours using the Aminex HPX-87H Column with dual refractive index and UV detection. Since molasses was one of the components, carboxylic acids existed in the broth prior to fermentation at 0 hours. After 24 hours there was a reduction in carbohydrates while glycerol and alcohol were being produced. At 96 hours most fermentable carbohydrates were consumed (Figure 1). This fast and easy method for analyzing the major parameters of fermentation allows production scientists to accurately measure fermentation kinetics. This method is particularly useful for evaluating strains of yeast and bacteria for efficient alcohol production.

Fig 1. Analysis of fermentation broths on the Aminex HPX-87H Column.

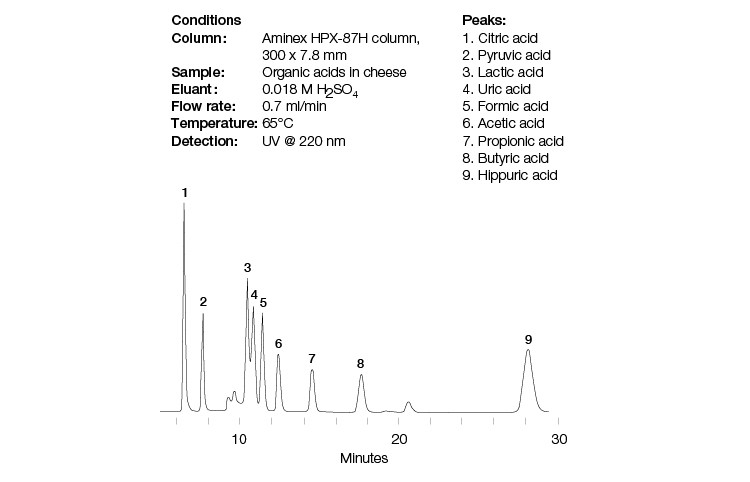

The Aminex HPX-87H Column also provides a method for better control over the production of cultured dairy products such as sour cream, yogurt, and cheese. Each culture produces a distinct organic acid profile, which can be used to monitor the microbiological process and to define the final product. These organic acid characteristics give food production analysts the capability to correlate levels of individual organic acids with the specific taste desired in a product (Figure 2).

Fig 2. Analysis of organic acids in cheddar cheese on the Aminex HPX-87H Column. Reproduced with permission. Bouzas J, et al. (1991). Simultaneous Determination of Sugars and Organic Acids in Cheddar Cheese by High‐Performance Liquid Chromatography. J Food Sci 56, 276.

View the complete line of columns here.

For a series of interesting discussions about the foods we consume, check out the following Hanging with my Chromies podcast episodes:

Episode 1: Barley, Yeast, and Hops . . . Oh My!

Episode 7: Pass the Curds, Please!

Episode 12: Can You Pick What’s Organic?

References

BIO-RAD and AMINEX are trademarks of Bio-Rad Laboratories, Inc. in certain jurisdictions.